Precision mold development process and production technology requirements and precautions

Precision molds are those that can produce plastic products with extremely high dimensional accuracy (usually between 0.02 and 0.005). The size control requirements of this mold are extremely strict, which involves many aspects:

Design attention key points

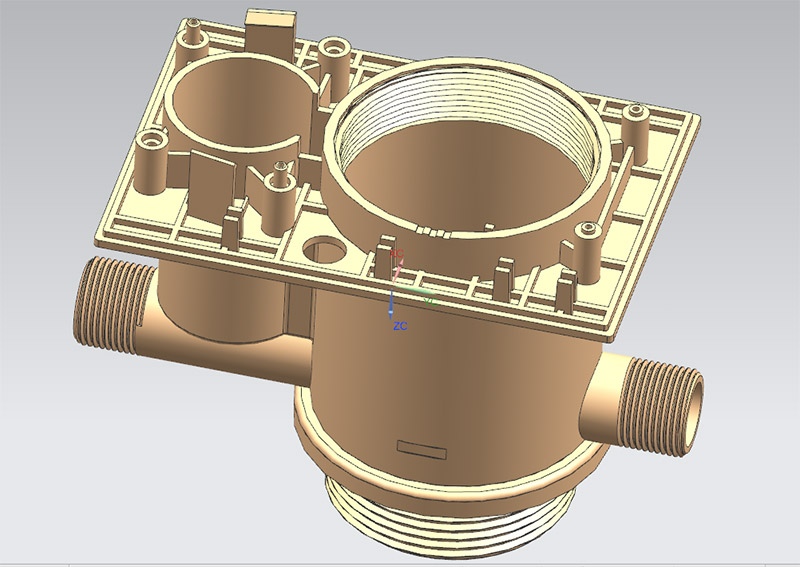

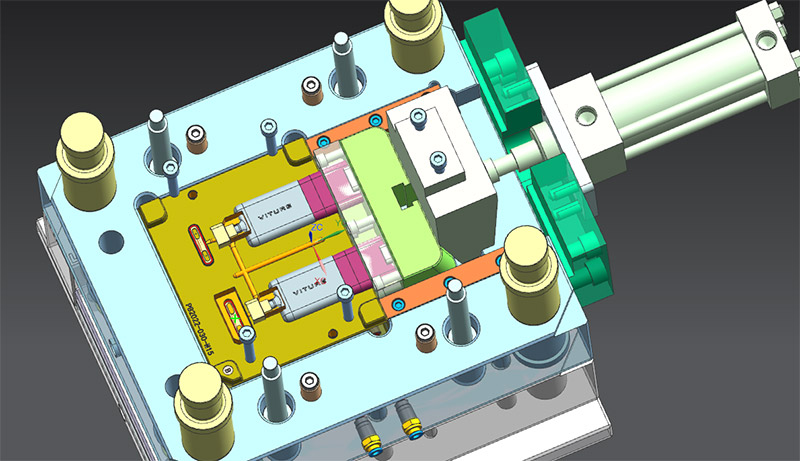

Shrinkage rate of plastic: The shrinkage rate of plastic material must be considered when designing the mold to ensure the dimensional accuracy of the final product. Product shape and size: Mold design must accurately reflect the shape and size requirements of plastic products.

The accuracy of the mold plastic parts: the accuracy of the mold directly affects the accuracy of the plastic products, and needs to be strictly controlled. Mold processing accuracy: The accuracy of mold processing is a necessary condition for precision injection molding, and it needs to rely on high-precision mold processing equipment.

The accuracy of the injection molding machine is also an important factor affecting the accuracy of the product, including injection pressure, injection speed and so on.

Precision mold development process and production technology requirements and precaution

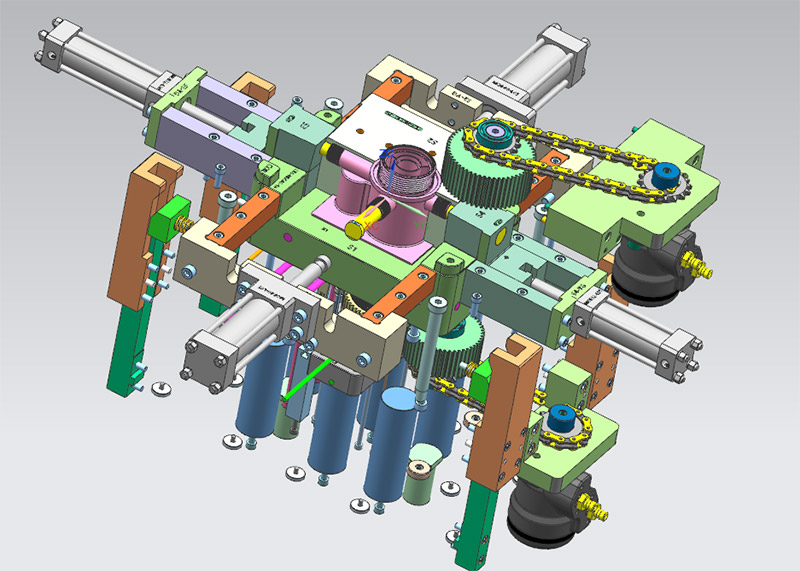

The development process of precision mold includes the following steps:

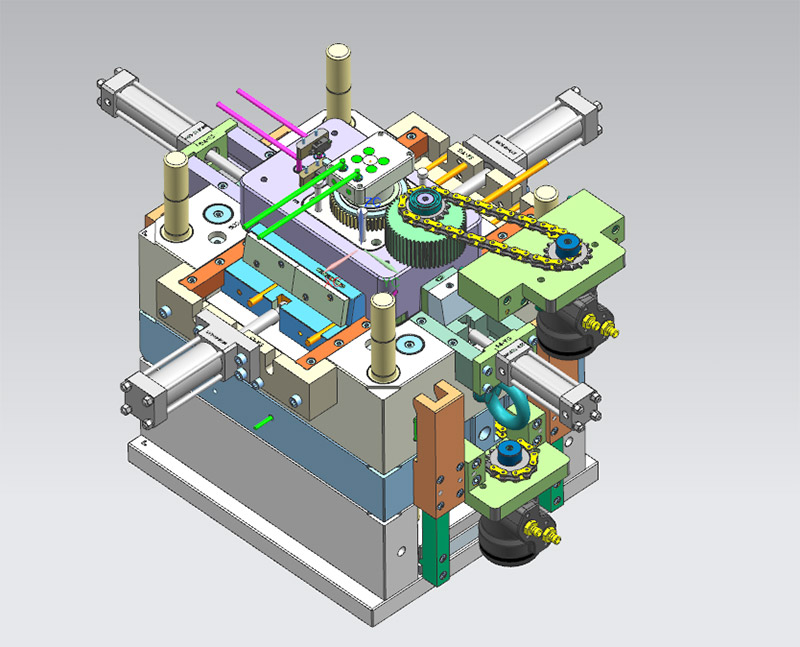

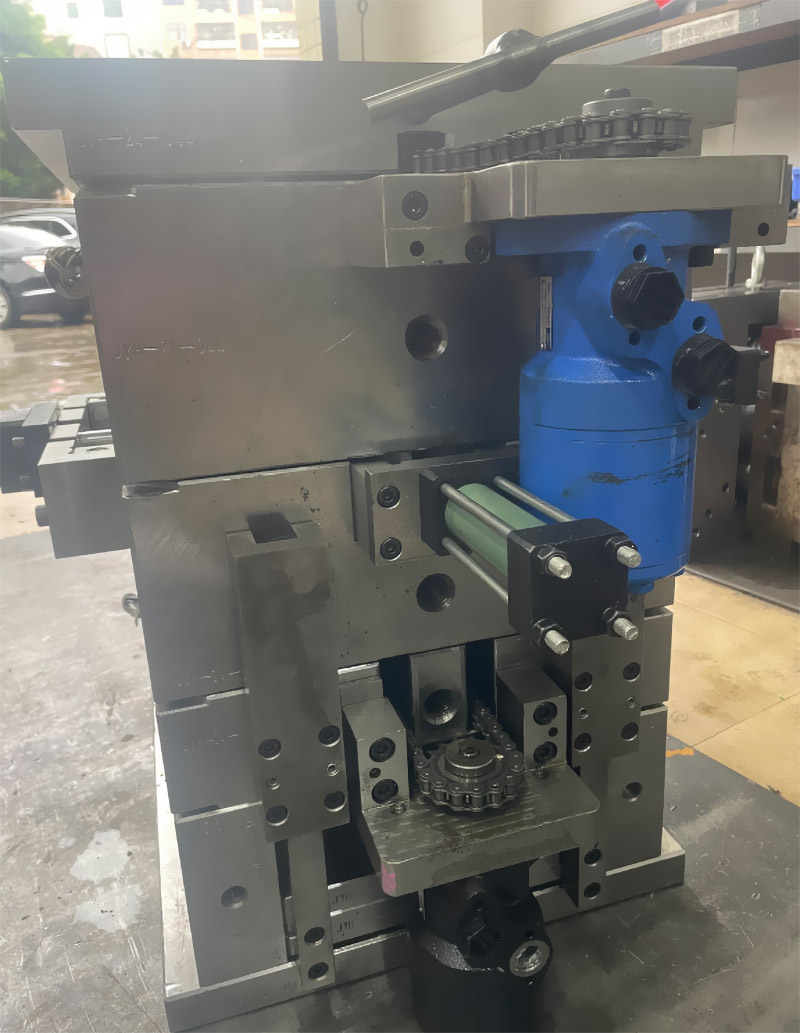

Mold development and design: Before development, we must collect and understand customer information, including product drawing size requirements, measurement benchmarks, tolerance of unmarked tolerance dimensions, etc., and get customer confirmation. Mold product process research and development: technical indicators include mold precision parts processing requirements of ±0.005mm, mold cumulative step error of ±0.02mm. Process scheduling analysis: including product analysis, layout optimization, process scheduling, mold processing, process testing, customer acceptance, assembly and debugging.

Note: In the mold processing process, special attention needs to be paid to the accuracy and durability of the mold, as well as the selection of the mold material and the heat treatment process to ensure the long-term stability and production efficiency of the mold. Precision injection molding plastic products are widely used in aerospace, auto parts, precision instruments, sports equipment, testing tools and other fields, these fields have extremely high requirements for the dimensional accuracy and quality of plastic products.

Process characteristics of precision injection molding technology

Injection pressure and speed: precision injection molding requires large injection pressure and speed to improve the compactness of plastic parts, reduce shrinkage deformation, and ensure the accuracy of parts. Pressure preservation: Pressure preservation has a great impact on precision plastic parts and requires precise control to ensure the dimensional stability of plastic parts.

Mold temperature control: the temperature change of the surface of the mold cavity should be controlled within ±1℃ to ensure the dimensional accuracy and quality of the plastic parts. Cooling system: Proper cooling is essential to achieve the desired part performance, dimensional accuracy, and to minimize warping or deformation.

Precision injection molding materials and process processing

The selection of precision injection molding materials needs to consider the fluidity, shrinkage, thermal stability and other factors of the material to ensure the quality of the final product. Process processing involves the pre-treatment, melting, injection molding, cooling and curing, mold opening and removal, and post-treatment of plastic particles

Recommended

- -Precision mold development process and production technology requirements and precautions

2024-11-16 - -Technical characteristics of two-color mold

2024-11-16 - -Optimizing Plastic Mold Development with Strategic Material Selection

2024-11-05 - -Plastic box mold: a tool to improve packaging efficiency

2024-10-26 - -The essence of the injection molding process: the fusion of precision and efficiency

2024-10-26 - -Quality management in plastic mold manufacturing

2024-10-26 - -The fine process of mold manufacturing from design to completion

2024-10-26 - -Refined: the essence of plastic mold design

2024-10-26 - -In-depth analysis of injection mold pricing: cost composition and optimization strategy

2024-10-26 - -What is the best practice for sourcing injection moulded parts from China

2024-10-26