About us

Pinbo Technology is adept at working with startups and companies pioneering new product ideas. By offering specialized services in mold design and plastic injection molding, we provide a cost-effective and efficient pathway from concept to market. Our expertise ensures that even the most innovative projects are realized with precision and quality, helping our clients turn their visions into successful products.

Introduction

Pinbo Technology Co., Ltd.

Located in Chang'an Town, Dongguan City, Guangdong, China, Pinbo Technology was established in June 2011. As a comprehensive technology-oriented enterprise, we provide one-stop product solutions. Our business scope includes research and development, production and sales, and technology transfer of electronic products, audio equipment, hardware, plastic products, leather goods, packaging products, crafts and accessories, daily necessities; as well as import and export of goods and technologies.

Leading Products

Our main products include e-cigarettes, accessories for office supplies, casings for electronic devices, protective cases for smartphones, and other plastic products for automotive use.

Key Clients

Our principal clients include internationally renowned brands such as Kyoto Denshi, FLLKE, and Tesla.

Company Departments

Pinbo Technology is structured into several departments to streamline operations and enhance product quality:

- Design Department

- CNC Machining Workshop

- EDM Machining Workshop

- Mold Assembly Workshop

- Injection Molding Processing Workshop

- PCBA SMT Workshop

- Product Assembly Workshop

These departments work together to provide a one-stop solution that reduces costs and enhances operational efficiency for our clients.

Established

- Founded: June 2011

- Departments: Design, Mold, Injection Molding, Quality Control, Finished Product Assembly.

- Production Facilities: CNC Precision Machining Workshop, Tooling and Die Fitting Workshop, Injection Molding Workshop, Assembly Workshop.

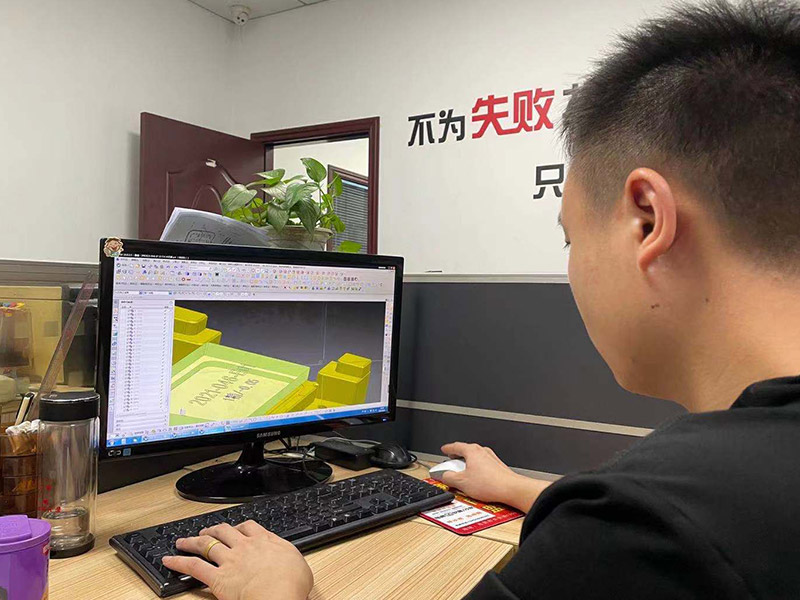

Mold and Product R&D

The Design Department at Pinbo Technology Co., Ltd. includes customer product optimization, mold structure design, and the design of tooling and fixtures. It is fully staffed with experienced engineers who have a strong awareness of product structure. Focused on the functional requirements of products, the department leads the development of new structures and processes with a forward-looking approach to technology.

CNC Machining (Mold)

The CNC machining center equipment determines the accuracy of the mold processing, and the German roders RXP500 high-speed machine can better control the quality of the mold.

| Model | Brand/Origin | Date of Entry | Dimensions (mm) | Machining Tolerance |

|---|---|---|---|---|

| CNC-RXP500 | Roders/Germany | 2019-04-01 | 500x400x400 | 0--0.005 |

| CNC-RXP500 | Roders/Germany | 2016-08-01 | 500x400x400 | 0--0.005 |

| CNC-V-800 | Roders/Germany | 2014-11-01 | 800x700x400 | 0--0.01 |

| CNC-640 | Moriseiki/Japan | 2019-08-01 | 660x450x400 | 0--0.01 |

| CNC-966 | Sheng Hong/China | 2024-04-01 | 900x600x500 | 0--0.15 |

| CNC-1000 | Darley/Taiwan | 2020-04-01 | 1000x600x600 | 0--0.015 |

| CNC-800 | Li Gong/Taiwan | 2023-03-01 | 800x500x400 | 0--0.01 |

| CNC-1100 | Taichung/China | 2013-09-01 | 1000x600x600 | 0--0.025 |

CNC Machining Equipment:

- High Precision:

- 0-0.005 mm: 2 units

- 0-0.01 mm: 3 units

- 0-0.015 mm: 2 units

- 0-0.025 mm: 1 unit

Specialized CNC Machines:

- German Roders High-Speed CNC: 5 units

- Japanese Mori Seiki Mid-Speed CNC: 2 units

- Standard CNC: 1 unit

EDM Processing (Mold)

EDM processing is an essential part of mold manufacturing. It plays a critical role in the production of molds for industries such as automotive, consumer electronics (including smartphones and digital cameras), aerospace, and medical device manufacturing. Our facility is equipped with state-of-the-art EDM machines that provide professional support and services tailored to these demanding sectors.

Device list:

These models cater to various mold manufacturing specifications and requirements.

- Sodick AD30LS

- Sodick AM30LS

- Sodick AM3L

- 0-0.002 mm: Part of our ultra-precision machining capabilities.

- 0.002-0.005 mm: Ensures high precision for more detailed applications.

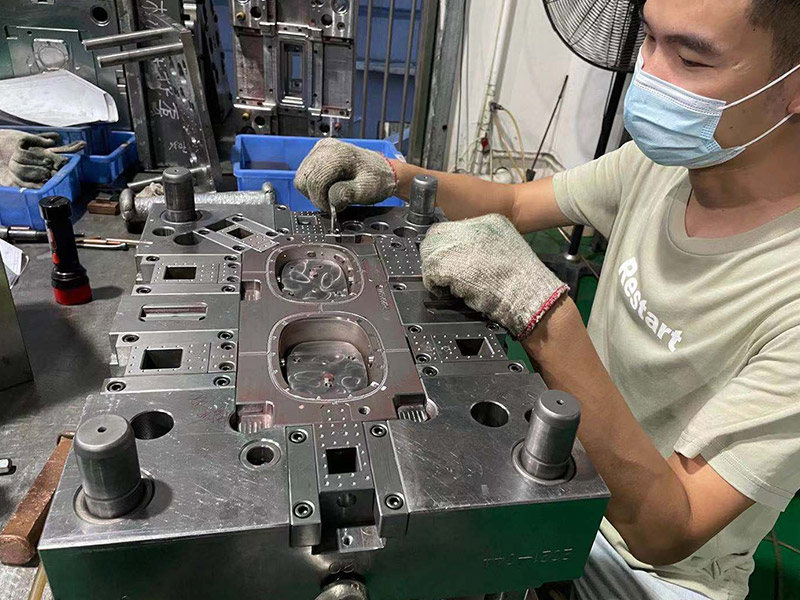

Fitter Assembly (Mold)

The Fitter Assembly Workshop is the crucial final stage in our mold production process, where experienced technicians assemble precision mold components before injection molding.

Expertise:

Our team specializes in assembling molds for:

- Precision tools

- 3C electronic casings

- E-cigarettes

- Smartphone protective cases

Capacity:

We handle molds up to 1.5 meters, ensuring versatility and precision across various product dimensions.

Injection molding

Our injection molding department is equipped with 23 state-of-the-art machines, ranging from 168 tons to 500 tons, capable of meeting diverse product specifications. This variety allows us to produce everything from precision components to 3C electronic casings and office supplies efficiently.

Machine Specifications:

- 168 tons: 6 machines

- 180 tons: 5 machines

- 200 tons: 4 machines

- 280 tons: 3 machines

- 350 tons: 3 machines

- 500 tons: 2 machines

Quality Control

Our quality department performs meticulous inspections on mold processing components, addressing critical requirements such as high dimensional accuracy, precise tolerances, and complex curvatures. We primarily utilize advanced metrology equipment, including:

- CMM (Coordinate Measuring Machine): For three-dimensional inspections.

- Surface Plates: For two-dimensional checks.

Standards:

Each component must pass these stringent inspections and meet the designed tolerances before assembly can proceed, ensuring the highest quality and precision in the final molds.

Injection Molding Quality Control:

In our injection molding department, quality control is equally stringent:

- Main Inspection Tools: 2D measuring instruments and calipers are the primary tools used.

- Staff: Every operator is also a trained inspector, ensuring continuous quality control.

- Procedures: Each shift includes randomly assigned inspectors who conduct spontaneous on-site and pre-shipment inspections.