The essence of the injection molding process: the fusion of precision and efficiency

Injection molding is an efficient and widely used manufacturing technique that works by injecting molten plastic into precision molds that are cooled to form the desired plastic parts. The attention to detail and precision required by this process ensure that the final product meets the exacting specifications. The following are the key steps of the injection molding process, explained from the perspective of Pinbo's senior mold development engineer:

1. Material preparation : First, the plastic raw material (usually granular) is added to the hopper of the injection molding machine, ready for melting and injection.

2. Injection : The plastic material is heated to a molten state inside the injection molding machine, and then injected into the mold cavity through the pouring system under high pressure.

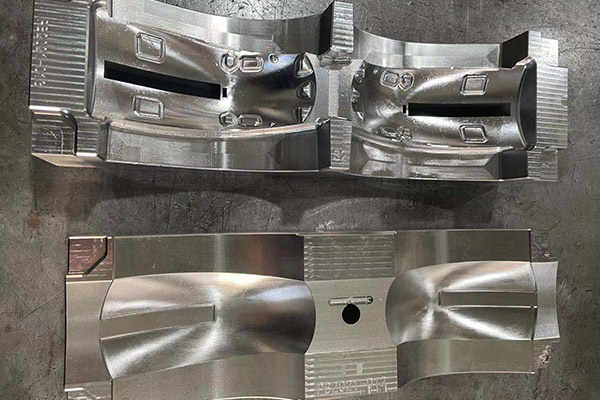

3. Cooling solidification : The plastic material injected into the mold cavity is cooled and solidified in the mold to form the precise shape required for the final product.

4. Mold opening : After the plastic material is completely solidified, the mold is opened and ready to release the molded product.

5. Ejection : Use the ejector rod to push the molded product out of the mold to complete the entire injection molding process.

6. Post-processing : As required, the molded product may undergo secondary operations such as trimming, drilling or assembly to achieve the desired state of the final product.

The success of the injection molding process lies in the precise control of each step, including the adjustment of temperature, pressure, injection speed and cooling time. The optimization of these parameters ensures the quality and consistency of the product to meet the needs of different application areas. With carefully designed molds and precisely controlled injection molding machines, even the most complex plastic parts can be produced efficiently and economically.

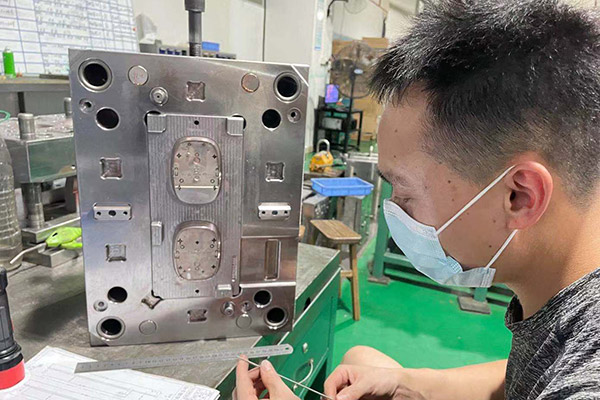

Throughout the injection molding process, quality control plays a crucial role. From design review to material selection, to processing, heat treatment, polishing and mold assembly, every step is rigorously inspected and tested to ensure the quality of the mold and the final product. Mold testing is an important link before production, which ensures that the mold can produce products that meet the specifications. The maintenance and repair of the mold ensures the quality and stability in long-term production.

Every step of the injection molding process is a test of precision and detail, and Pinbo, with years of experience and technology accumulation, is able to ensure that every injection can achieve the desired effect, providing customers with high-quality plastic parts and products.

Recommended

- -Precision mold development process and production technology requirements and precautions

2024-11-16 - -Technical characteristics of two-color mold

2024-11-16 - -Optimizing Plastic Mold Development with Strategic Material Selection

2024-11-05 - -Plastic box mold: a tool to improve packaging efficiency

2024-10-26 - -The essence of the injection molding process: the fusion of precision and efficiency

2024-10-26 - -Quality management in plastic mold manufacturing

2024-10-26 - -The fine process of mold manufacturing from design to completion

2024-10-26 - -Refined: the essence of plastic mold design

2024-10-26 - -In-depth analysis of injection mold pricing: cost composition and optimization strategy

2024-10-26 - -What is the best practice for sourcing injection moulded parts from China

2024-10-26