Quality management in plastic mold manufacturing

In the field of plastic mold manufacturing, quality control is a key link to ensure that the mold and the plastic parts produced meet the specifications. As a senior mold development engineer at Pinbo, I know how accurate execution of each process affects the final product. Below are some of the key quality control measures we implement in the plastic mold manufacturing process.

Key link of quality control

1. Design review : At the beginning of mold manufacturing, we will conduct a comprehensive review of the mold design to ensure that the design not only meets the specifications, but also is suitable for its intended use.

2. Material selection : We carefully select high-quality materials suitable for various mold requirements, because the quality of materials directly affects the performance and durability of the mold.

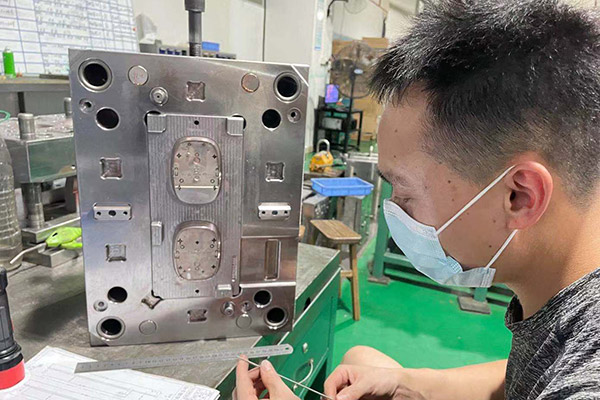

3. Inspection and testing : At every stage of manufacturing, the mold is subjected to rigorous inspection and testing, including dimensional measurement, surface finish inspection and hardness testing to ensure that it meets manufacturing specifications.

4. Assembly inspection : After the mold components are manufactured, we will carry out assembly inspection to ensure the accurate fit and alignment of each part, which is a key step to ensure the normal operation of the mold.

5. Mold test : Before the mold is officially put into production, we will carry out tests to verify that the plastic parts produced meet the specifications and quality standards.

6. Maintenance and repair : We recognize that proper maintenance and timely repair of molds is critical to maintaining their ability to produce high-quality parts over the long term.

Importance of quality control

Overall, quality control measures are essential to ensure that plastic mold manufacturing meets specifications and produces high-quality molds that meet the needs of the intended application. Through these meticulous measures, we are able to ensure that every detail of the mold meets the highest quality standards, thereby avoiding costly defects and the risk of product rejection.

At Pinbo, our commitment to quality is reflected in the care we take with each mold. Our quality control process is part of our commitment to our customers, ensuring that they receive not just molds, but Pinbo's guarantee of exceptional quality. Through continuous quality control and improvement, we constantly push the plastic mold manufacturing industry forward, providing our customers with the high quality solutions they rely on.

Recommended

- -Precision mold development process and production technology requirements and precautions

2024-11-16 - -Technical characteristics of two-color mold

2024-11-16 - -Optimizing Plastic Mold Development with Strategic Material Selection

2024-11-05 - -Plastic box mold: a tool to improve packaging efficiency

2024-10-26 - -The essence of the injection molding process: the fusion of precision and efficiency

2024-10-26 - -Quality management in plastic mold manufacturing

2024-10-26 - -The fine process of mold manufacturing from design to completion

2024-10-26 - -Refined: the essence of plastic mold design

2024-10-26 - -In-depth analysis of injection mold pricing: cost composition and optimization strategy

2024-10-26 - -What is the best practice for sourcing injection moulded parts from China

2024-10-26