What is the difference between injection mold and blow mold?

In the manufacturing of plastic products, injection molding and blow molding are two distinct molding technologies, each of which is suitable for specific product needs and application scenarios. As a senior mold development engineer, I will delve into the differences between these two mold processes and their application in actual production.

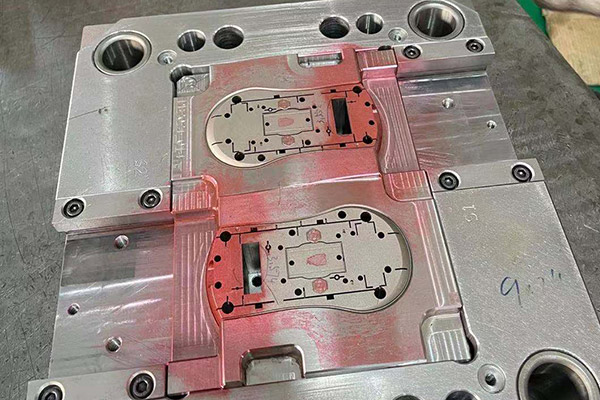

Injection mold process details:

The injection mold process is a high-precision manufacturing method that uses pressure to shape the material by injecting molten plastic material into a precision mold cavity. Injection molded products are usually solid and can replicate all the details within the mold at one time, such as bumps, stiffeners, threads, etc. Parts after injection molding can usually be used as a final product without additional processing, which makes injection molds ideal for the production of plastic parts with complex shapes and high precision requirements.

Blow mold process analysis:

Blow molding, also known as hollow blow molding, is a process used to make hollow plastic products. The process involves placing a thermoplastic raw material into a mold and then creating the desired hollow shape by injecting compressed air to expand the material and fit the inside wall of the mold. The blow molding process is particularly suitable for the production of large or simple shaped hollow products such as bottles, drums and fuel tanks. Compared with injection molds, parts produced by blow molds are usually thinner and more transparent, and have higher requirements for the toughness and tensile properties of materials.

The difference between injection molding and blow molding:

The main difference between injection moulds and blow moulds is their product design and application. Injection moulds are suitable for the production of solid, detailed products, while blow moulds focus on the manufacture of thin-walled, transparent and usually hollow products. The production process of injection molds is usually simpler and has relatively low requirements for raw materials, while blow molds require higher processing accuracy and higher quality raw materials.

Summary:

Injection moulds and blow moulds each have their own unique advantages and application areas. Injection moulds are favored for their precise detail reproduction and solid product manufacturing capabilities, while blow moulds are widely used in various industries for their high transparency and toughness in the production of thin-walled hollow products. With the continuous progress of plastic processing technology, these two mold processes have shown broad prospects for development, and will continue to play a key role in the manufacture of daily necessities and industrial products. At Pinbo, we are committed to using these advanced mold technologies to provide our customers with high-quality plastic product solutions.

Recommended

- -What kind of enterprise is Pinbo Technology

2024-11-21 - -Pinbo Tech FAQ

2024-10-26 - -What is the difference between injection mold and blow mold?

2024-10-26 - -What are the key design elements for creating a rugged toolbox mold?

2024-10-26 - -What are the mold manufacturing guidelines for custom plastic products?

2024-10-26 - -Choose the right mold material?

2024-10-26 - -What is a plastic mold?

2024-10-26 - -What is injection molding?

2024-10-26 - -Analysis of key points in plastic product structure design

2023-12-22 - -Analysis of two-color injection molding and insert injection molding technology

2023-12-22